Essential Safety Tips for DIY Furniture Recycling and Upcycling Projects

Mar 19th 2025

Recycling and repurposing furniture at home can be a rewarding and sustainable way to give old pieces new life. However, these projects require careful planning and strict safety measures to prevent injuries and protect your workspace.

This guide provides essential safety tips to help homeowners handle furniture recycling and repurposing projects with confidence.

Essential Personal Protective Equipment for Furniture Projects

When recycling and repurposing furniture, appropriate personal protective equipment (PPE) is paramount to ensure safety and mitigate the risk of injury. The selection of PPE should be based on the specific tasks being performed and the materials involved.

Protecting the Eyes

The American Academy of Ophthalmology reports that proper eye protection can prevent 90% of work-related eye injuries. Protecting your eyes is especially important when recycling furniture. Tasks such as sanding, stripping paint, and cutting wood release dust, debris, and chemical particles.

Old finishes and adhesives may contain harsh chemicals that irritate or damage the eyes, making protective eyewear essential. By wearing the right gear, you can work safely and focus on giving new life to old furniture.

Hand Protection

Gloves protect hands from cuts, abrasions, and chemical exposure. Heavy-duty work gloves made from leather or synthetic blends are recommended for handling rough wooden surfaces, assembling furniture, and sanding edges.

When working with wood stains, varnishes, or strong adhesives, chemical-resistant gloves made of nitrile or neoprene should be worn to prevent skin contact and potential chemical burns.

Respiratory Safety

Respiratory protection is essential when handling materials that release dust, fumes, or vapors. A dust mask or respirator with a particulate filter is necessary when sanding wood, cutting wooden panels, or working with medium-density fiberboard.

Tasks that involve spray paints, furniture polish, or wood sealants require a respirator with an organic vapor cartridge to block toxic fumes.

Preventing Hearing

Hearing protection is essential when working on DIY furniture upcycling projects, especially when using loud tools such as electric sanders, power drills, or circular saws.

According to the American Speech-Language-Hearing Association (ASHA), exposure to sounds at 85 dBA for more than 8 hours can lead to hearing loss. To prevent long-term damage, noise-reducing earmuffs or foam earplugs should be a key part of your PPE when upcycling furniture.

Tips to Avoid Injury When Reassembling Furniture

Reassembling furniture comes with various risks when not handled with caution and precision. Mitigating the potential for injury requires following these essential practices:

Ergonomic Posture

|

Maintaining an ergonomic posture to prevent musculoskeletal strain is advisable when handling components. This includes keeping the back straight and bending at the knees when lifting heavy parts. |

Secure Fastening

|

Over-tightening screws or bolts can compromise the material, leading to potential structural failure. Conversely, under-tightening can result in instability. A torque wrench can provide the necessary control to apply the correct force, thereby maintaining the balance between security and material preservation. |

Stability Testing

|

It is essential to conduct a stability test once reassembly is complete. This involves applying pressure to various furniture points to ensure it remains stable and does not wobble or tip. |

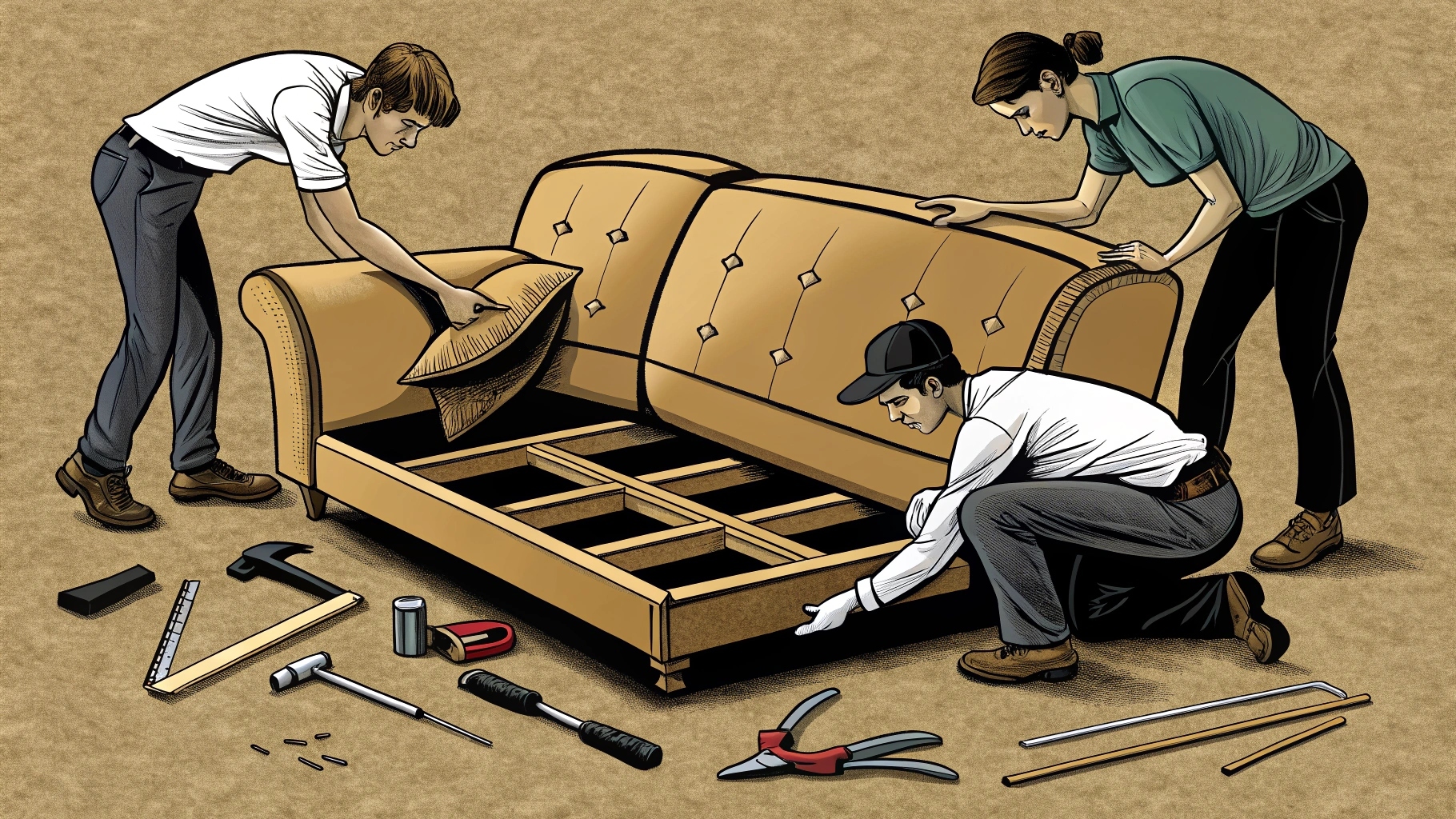

How to Get Furniture Ready for Recycling

Preparing furniture for recycling requires a systematic approach to ensure efficiency and safety. The process includes these key steps:

Cleaning

Begin by thoroughly cleaning the furniture to remove dust, dirt, and any surface contaminants. This can be achieved using appropriate cleaning agents that are safe for the material in question, such as mild detergents for wood and metal or specialized fabric cleaners for upholstered items.

Material Identification and Disassembly

Accurately identify the materials that constitute the furniture. This includes distinguishing between recyclable and non-recyclable components.

Carefully disassemble the furniture to separate different materials. The table below outlines the essential tools for safe and effective furniture disassembly and their best use cases.

|

Tool Type |

Best Use Case |

Safety Tip |

|

Screwdrivers and wrenches |

Unscrewing bolts, disassembly |

Use the correct size to avoid stripping screws |

|

Rubber mallet |

Separating delicate furniture parts |

Avoid excessive force on fragile wood |

|

Utility knife |

Removing upholstery, separating joints |

Use sharp blades for clean cuts |

|

Pry bar, putty knife |

Removing adhered furniture parts |

Apply even pressure to prevent breakage |

|

Cordless drill, jigsaw |

Disassembling larger parts quickly |

Ensure proper grip & keep fingers away from the blade |

After you’re done with disassembly, label and sort the disassembled parts according to their material type to facilitate recycling.

Documentation and Transport

Document the types and quantities of materials prepared for recycling. This documentation is essential for tracking and reporting purposes, especially when dealing with regulated materials.

Arrange for the transport of recyclable materials to appropriate recycling facilities. Ensure that the transport method complies with safety standards to prevent damage or spillage during transit.

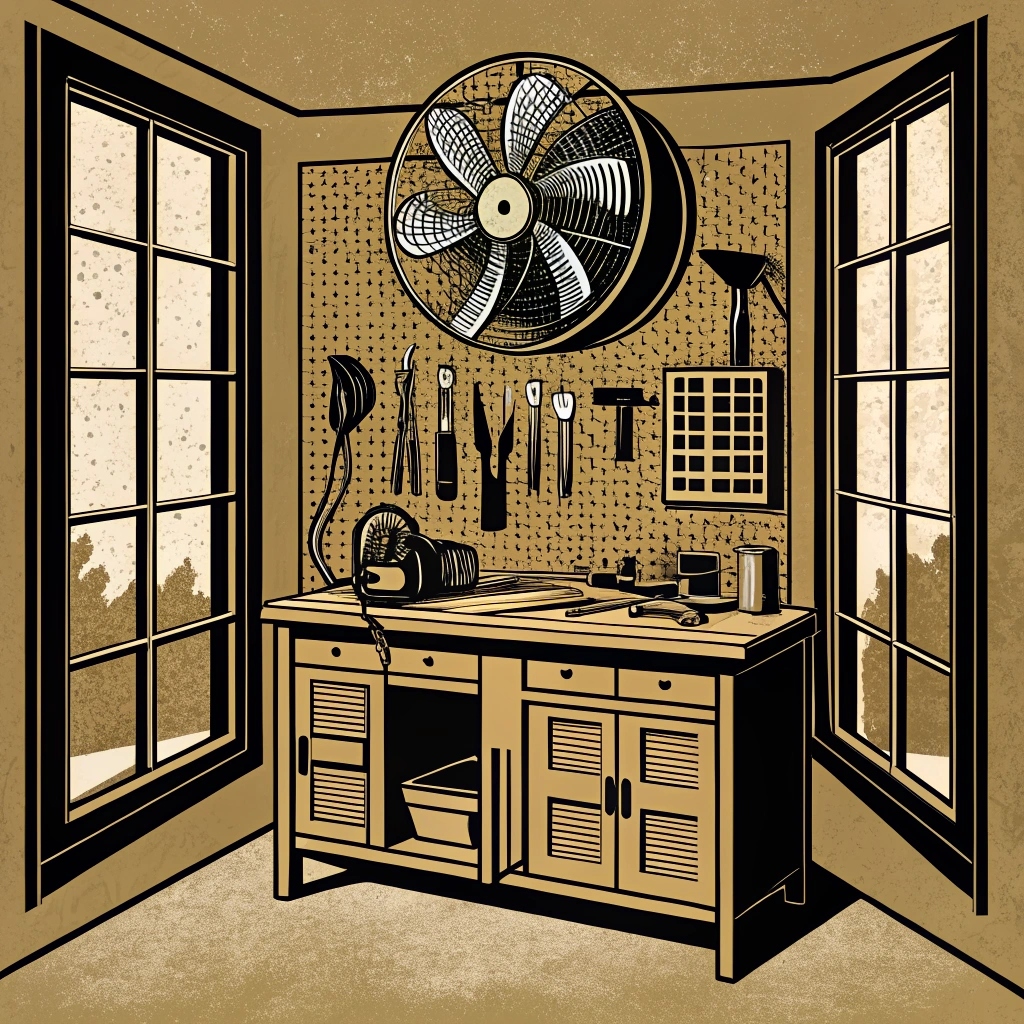

Ensuring a Safe Workspace for Furniture Projects

Several factors must be considered to ensure a workspace is safe for furniture projects. The workspace should be organized to minimize hazards and facilitate efficient movement.

Ensure a safe and efficient workspace with these essential tips for furniture projects:

Proper Lighting

|

Proper illumination helps reduce errors and accidents. While natural light is ideal, bright and evenly distributed artificial lighting is a great alternative. Task lighting, such as adjustable lamps, can be used to focus on specific areas, ensuring precision in detailed work. |

Adequate Ventilation

|

A well-ventilated area helps dissipate fumes, reducing inhalation risks. This can be achieved using exhaust fans, open windows, or air filtration systems designed to handle chemical particulates. |

Organizing Tools and Materials

|

Tools should be stored in designated areas, such as toolboxes or wall-mounted racks, to prevent tripping hazards and ensure they are readily accessible. Materials, especially those that are flammable or hazardous, should be stored in compliance with safety regulations, often in fire-resistant cabinets or containers. |

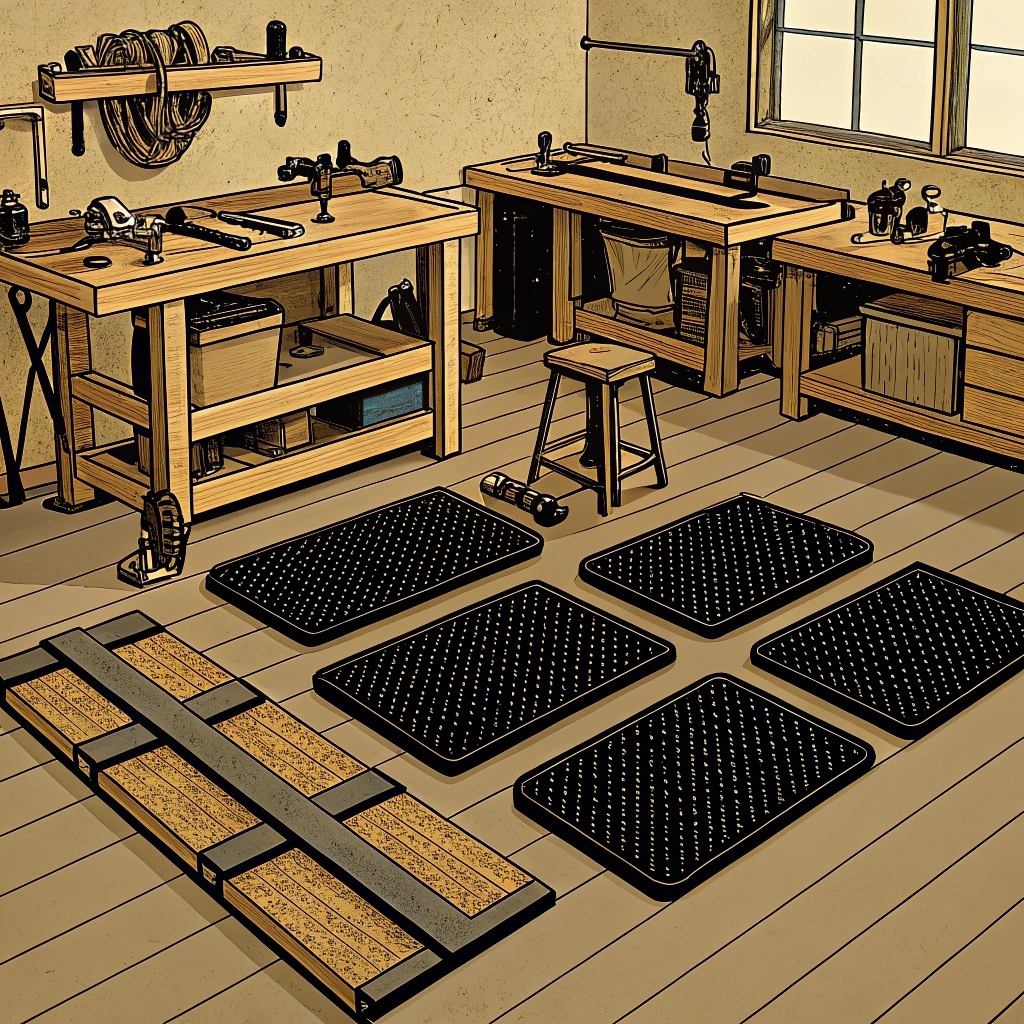

Keeping the Floor Clean

|

The workspace's floor should be kept clean and free of debris. Non-slip mats, particularly in areas where liquids are used, can reduce the risk of slips and falls. Regular maintenance of the workspace, including inspecting electrical outlets and cords for wear and tear, is necessary to prevent electrical hazards. |

Best Practices for Using Power Tools

Adhering to best practices is essential for ensuring safety and efficiency when using power tools to recycle and repurpose furniture.

One of the most important factors is selecting the right tool for the job. Using improper tools increases the risk of accidents and injuries. In fact, the Alabama League of Municipalities, an independent organization dedicated to advocating for and assisting Alabama's municipalities, reports that hand tool-related incidents account for approximately 8% of all workplace injuries, some of which can result in serious consequences such as finger or eye loss.

Using each tool as intended is essential to preventing such injuries. Every tool is designed for a specific function, and choosing the correct one enhances safety and improves the quality of work.

With that in mind, here are key tips for safely and effectively using power tools for recycling and repurposing furniture:

Maintaining Power Tools

Regularly inspecting tools for wear and tear, such as frayed cords, loose parts, or dull blades, helps prevent malfunctions. Cleaning them after each use removes dust and debris that could hinder performance or cause overheating.

Additionally, lubricating moving parts, as the manufacturer recommends, ensures smooth operation and extends the tool’s lifespan.

Ensuring a Safe Workspace

The workspace environment must be organized and free of obstructions to facilitate safe tool operation. Adequate lighting is also essential to clearly see the workpiece and tool, reducing the likelihood of errors.

Additionally, it is important to ensure that the work area is dry and free from moisture, as water can increase the risk of electrical shock when using power tools.

Using Proper Personal Protective Equipment (PPE)

Personal protective equipment (PPE) is mandatory when operating power tools. This includes safety goggles to protect the eyes from flying debris, ear protection to mitigate noise exposure, and gloves to safeguard against cuts and abrasions.

In some cases, a dust mask or respirator may be necessary to prevent inhaling harmful particles, especially when cutting or sanding materials that produce fine dust.

Handling and Storing Tools Safely

Proper handling and operation of power tools are essential for safety and efficiency. Operators should maintain a firm grip and use both hands whenever possible for better control. Keeping fingers away from moving parts and ensuring the power cord remains untangled helps prevent accidents.

Tools should also be unplugged and stored securely to avoid unauthorized access or accidental activation when not in use.

The Association for Materials Protection and Performance emphasizes:

When handling hand and power tools, you also need to dress for the job. Avoid wearing loose-fitting clothing, jewelry, and neckties. Remove dangling objects of any kind before you start working. If you have long hair, tie it behind your head so that it doesn’t get in your way. When it comes to footwear, non-slip boots are recommended.

Safe Methods for Stripping Old Paint or Finish from Furniture

Safely removing old paint or finish from furniture requires using techniques that reduce health risks and protect the piece from damage.

Effective methods for restoring the original surface include:

Selecting the Right Stripping Agent

The process begins with selecting the right stripping agent. Chemical strippers, available in liquid, gel, or paste forms, are especially effective for removing multiple layers of paint or finish.

To achieve the best results, it's essential to choose a product suited to the specific finish type and carefully follow the manufacturer’s instructions.

Proper Ventilation and Safety

When using chemical strippers, minimizing exposure to harmful fumes is essential. Proper ventilation is the first line of defense. Whenever possible, work outdoors. If working indoors, open windows and doors and use fans to improve air circulation. Fumes can build up without adequate airflow, increasing the risk of inhalation.

In addition to airborne hazards, direct contact or prolonged exposure can also be dangerous. Many stripping chemicals are easily absorbed through the skin or inhaled, leading to irritation of the skin and eyes, headaches, dizziness, nausea, or loss of coordination.

Always wear appropriate personal protective equipment (PPE), including chemical-resistant gloves, safety goggles, and a respirator with organic vapor cartridges to protect yourself. These precautions will help reduce health risks and create a safer working environment.

Applying and Removing the Stripper

Use a brush to spread a thick, even layer of stripper over the surface. Let it sit for the recommended time, allowing the chemicals to break down the paint or finish effectively.

Once the coating begins to bubble or lift, carefully scrape it off with a plastic scraper to prevent damage to the underlying wood. Use a nylon brush or steel wool to reach tight spaces without harming the surface for intricate details or carvings.

Cleaning and Neutralizing the Surface

After most of the finish has been removed, a thorough cleaning is essential. Wipe down the surface with a solvent like mineral spirits or denatured alcohol to eliminate any remaining residue and neutralize the stripper. This step ensures proper adhesion for the new finish.

All waste materials, including used strippers and paint debris, must be disposed of according to local hazardous waste regulations to prevent environmental contamination.

Alternative Methods for Paint Removal

If chemical strippers are unsuitable, alternative methods such as heat guns or infrared paint removers can be used. These tools soften the paint, allowing easy removal without chemicals.

However, if working with lead-based paint, extra care is needed to avoid scorching the wood or releasing toxic lead fumes. Testing for lead paint before beginning any stripping process on older furniture is strongly recommended.

U.S. General Services Administration, a federal agency responsible for overseeing and maintaining government-owned properties, emphasizes:

Paint removal using thermal methods can release lead fumes into the air, and inhalation of that vapor can cause lead poisoning through inhalation. Children are particularly susceptible to very low doses. Higher-temperature paint removal methods present greater lead fume risks, so the lowest temperature method possible should be used.

Difference Between Upholstered and Wooden Furniture Recycling

Recycling upholstered and wooden furniture involves different techniques to ensure durability, safety, and sustainability.

Upholstered furniture requires careful fabric removal, deep cleaning, and material selection, while wooden furniture focuses on structural repairs, sanding, and protective finishes.

The table below highlights key considerations for both types.

|

Factor |

Upholstered Furniture |

Wooden Furniture |

|

Initial Assessment |

Inspect for fabric wear, dust, and allergens. |

Check for rot, insect damage, and weak joints. |

|

Preparation Process |

Remove fabric using staple removers and pliers to avoid damaging the frame. |

Repair weak joints, replace damaged sections, and fill cracks with wood filler. |

|

Cleaning & Treatment |

Steam cleaning eliminates bacteria and allergens, making fabrics safe for reuse. |

Sanding with grit paper removes old finishes and improves surface adhesion. |

|

Final Protection |

Ensure longevity with high-quality fabric and padding. Upholstery may need replacement over time. |

Apply a UV-resistant sealant to protect against sunlight damage. |

Effective Methods for Reinforcing Furniture

Reinforcing techniques are essential to ensure repurposed furniture's structural integrity and longevity.

The primary objective is to enhance the strength and stability of the furniture, ensuring it can withstand regular use. The following methods can be employed to achieve this:

Reinforce with Dowels

These small, cylindrical rods or flat, oval-shaped pieces are inserted into pre-drilled holes in adjoining pieces of wood.

Glued in place, they create a strong bond that enhances the connection between the pieces. This technique is especially beneficial in reinforcing joints subject to frequent movement or weight, such as those in chairs and tables.

Add Back Panels

Installing a back panel can increase stability for furniture that requires additional support, such as shelving units or bookcases.

A back panel, typically made of plywood, is attached to the rear of the unit. This prevents lateral movement and provides a solid structure that helps maintain the shape and alignment of the furniture.

Install Support Beams

The use of additional support beams or crossbars can strengthen larger pieces of furniture, such as beds or large tables.

These components are installed beneath the furniture's surface, providing extra support and reducing the risk of sagging or collapsing under heavy loads.

Proper Storage and Disposal of Hazardous Materials After Repurposing Furniture

Proper storage and disposal of hazardous materials are essential to ensuring safety during furniture recycling projects.

Paints, solvents, adhesives, and certain types of finishes are hazardous materials commonly encountered in these activities. If not managed correctly, these substances can pose significant health and environmental risks.

Key tips for safely storing and disposing of hazardous materials to protect your health and the environment include:

Proper Storage

Hazardous materials must be kept in their original containers with labels intact to ensure easy identification and access to safety instructions.

Containers should be tightly sealed to prevent leaks and evaporation, which can lead to harmful fumes. These materials should be stored in a cool, dry, and well-ventilated area away from direct sunlight and sources of ignition.

Proper Disposal

Adhere to local regulations and guidelines when disposing of waste, as improper disposal can lead to environmental contamination and legal penalties.

Many communities offer household hazardous waste collection programs, which provide a safe and responsible way to dispose of these materials. It is important to never pour hazardous substances down the drain, on the ground, or into storm sewers, as this can lead to water pollution and harm aquatic life.

Eco-Friendly Alternatives

Several eco-friendly alternatives are available. Water-based paints and finishes, for example, are less hazardous and easier to clean up than their solvent-based counterparts.

Additionally, using natural solvents such as citrus-based cleaners can reduce the reliance on more harmful chemicals.

Individuals can minimize their environmental impact by choosing these alternatives while maintaining safety in their furniture recycling and repurposing projects.

Examples of Safe Practices for Repurposing Furniture

Repurposing furniture at home can be a creative and fulfilling experience, but it also comes with potential hazards. Proper safety measures can minimize risks and ensure a secure workspace.

Here are two case studies highlighting the importance of safe practices, from dust control to tool handling, and how they can be applied to home DIY projects.

Creating a Safer Environment in Furniture Workshops

A study conducted in the United States by the National Institute for Occupational Safety and Health (NIOSH) examined workplace safety in the wooden furniture manufacturing industry. The focus was on reducing occupational hazards and enhancing worker protection.

Several safety measures were implemented, including advanced dust control systems and mandatory PPE use. Employees also received training on safe lifting techniques, fire prevention strategies, and handling hazardous materials such as adhesives and lacquers.

These initiatives reduced workplace injuries and accidents and improved air quality due to enhanced dust extraction systems.

Applying similar safety practices in non-industrial settings can help individuals working on recycling furniture projects minimize risks.

Essential precautions include wearing protective gear, ensuring proper ventilation, and handling tools carefully. Tasks such as sanding, painting, and repurposing furniture require attention to dust control and chemical exposure.

By adopting these safety measures, furniture recyclers can maintain a secure workspace while embracing a creative and sustainable approach.

Safe Tool Handling for DIY Furniture Projects

A study on occupational injuries in the furniture industry examined accident trends in 18 factories over one year.

Researchers identified common hazards, assessed injury severity, and outlined key safety precautions. The findings showed that machine-related accidents—especially those involving cutting tools—were the most frequent, often with the potential for severe injury.

Notably, 66% of workplace accidents stemmed from worker actions and unsafe procedures.

This high rate of tool-related injuries highlights the importance of proper factory safety measures when recycling or repurposing furniture at home. Power tools such as saws, drills, and sanders can cause serious harm if mishandled.

Occupational Safety and Health Administration’s Hand and Power Tools guidelines emphasize the importance of proper tool use. Homeowners repurposing furniture should inspect their tools beforehand to ensure they are safe to use.

Power tools must have intact cords, proper grounding, and functional safety guards to prevent malfunctions.

Hand tools such as saws, hammers, and drills should be used correctly, following manufacturer instructions, to reduce the risk of injury or damage.

Protect Yourself While Repurposing Furniture

The process of recycling and repurposing furniture requires careful attention to safety, tool usage, and material management.

Taking the right precautions helps prevent injuries, maintain a well-organized workspace, and ensure responsible disposal of hazardous materials.

Safe furniture recycling offers more than just environmental benefits. It promotes sustainability, enhances creativity, and extends furniture life while reducing waste.

It's time to prioritize safety! Equip yourself with the right tools and protective gear, follow best practices, and create a secure workspace for your next furniture project.

References

- Ophthalmologists Say 90 Percent of Work-Related Eye Injuries Can be Avoided by Wearing Eye Protection. (n.d.). American Academy of Ophthalmology. https://www.aao.org/newsroom/news-releases/detail/90-percent-of-work-related-eye-injuries-avoidable

- Loud Noise Dangers. (n.d.). American Speech-Language-Hearing Association. https://www.asha.org/public/hearing/loud-noise-dangers/?srsltid=AfmBOooeXH4DXM4VyeTpbK1tN5SSflRX2J18FFqLkhWXwvY0-vasASEp

- Hand Tool Safety. (n.d.). Alabama League of Municipalities. https://almonline.org/Assets/Files/LossControl/ReferenceDocuments/Hand%20Tool%20Safety.pdf

- Health and safety guide for wooden furniture manufacturing. (n.d.). Centers for Disease Control and Prevention. https://stacks.cdc.gov/view/cdc/115484

- Occupational injuries in the Finnish furniture industry. (n.d.). National Library of Medicine. https://pubmed.ncbi.nlm.nih.gov/8837265/